Ready to use safety critical interfaces.

The CLEARSY Safety Controller is a pre-packaged 3U rack which offers a few safety critical inputs and outputs to speed up the design of custom safety solutions and to validate industrial strategy through proof of concepts. This controller enhances the existing portfolio of the CLEARSY Safety Platform by adding interfaces to the safety critical computer.

The CLEARSY Safety Platform is aimed at easing the development and the deployment of safety critical applications, up to SIL4.

The heart of the CLEARSY Safety Platform is powered by:

- A single board vital computer (SIL4) bundled on credit card sized printed circuit board (72.5x45mm). By default and to allow a full flexibility for the designer, the computer does not includes any external interfaces. The CLEARSY Safety Controller is aimed to fill this gap by providing already certified and deployed SIL4 output and input interfaces.

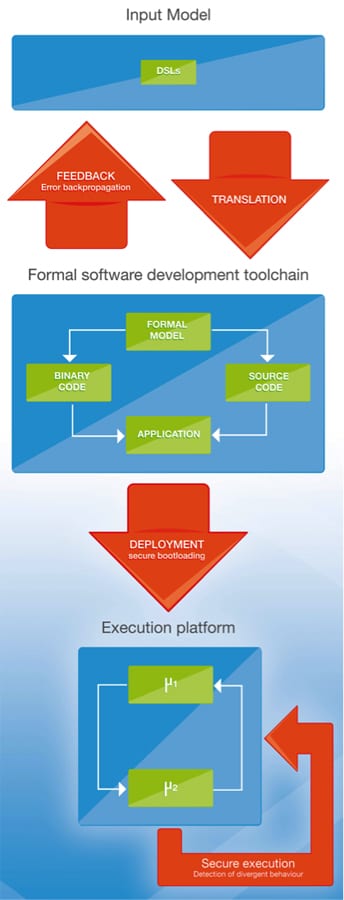

- A software library that includes all the safety principles required to reach a SIL4 execution level. This library is in charge of performing all the vital built-in health tests. This software library is formally proven with the B formal method.

- A fully integrated toolchain (certified T3 for generation and T2 for optional formal validation) allows building directly the final binary. Thanks to this setup, all the configuration and installation steps related to the tools’ ecosystem are completely avoided.

The CLEARSY Safety Platform is certified with a SIL4 level (certificate SIL4 CERTIFER n° 9594/0262) against the following standard:

- CENELEC EN50126:2017

- CENELEC EN50128:2011

- CENELEC EN50129:2018

|

|

|

Interfaces available

The CLEARSY Safety controller provides right out of the box:

– 3x voltage free double cut SIL4 outputs (switching current up to 8Amps),

– 4x SIL4 digital inputs (wide range 0..140 VDC),

– Ethernet interface (BASE10/100TX),

– Generic power source redundant (24VDC to 110VDC, other voltages available on demand),

– Realtime clock calendar and maintenance features included.

Customizable solution

The CLEARSY Safety Controller has to be seen as an initial outline for a custom design. It saves time for the first spin of hardware design and validation, but the CLEARSY Safety Controller can of course be fully updated, modified or enhanced to meet exactly specific requirements (form factor, IO count, specific interfaces as PWM, network, analog, …).

The CLEARSY Safety Controller reduces the overall development schedule and also design risks.

The possibility of using interfaces already deployed on real safety critical system and certified SIL4 allows our users to focus on their specific application instead of spending time to design safety critical drivers for common peripherals.

DEVELOPMENT PROCESS WITH THE CLEARSY SAFETY PLATFORM

The typical time frame for a new design of a safety critical solution with the CLEARSY Safety Controller is the following:

- Proof of concept (about 3 months) During this phase the CLEARSY safety controller is used to test the business logic and custom application with the default interfaces of the controller. In addition, custom interfaces can be designed and added to the controller as mock-up interfaces. Thanks to the fact that the hardware part is available right at the beginning of the project and with most of the classical interfaces available right out of the box, it is possible to demonstrate the feasability and compliance of the final product in a very short timing window.

- Custom solution design (about 12 months). Once the mock-up built has demonstrated the viability of the technical solution, a rework / finalization phase is started. Depending on the findings discovered during the previous phase, some interfaces might need some reworks or the form-factor could be updated. The purpose of this step is to build the final product and also to conduct all the required environmental, EMC, Vibration and Shock qualifications. At the end of this phase the product is certified and ready to be deployed.

- Serial manufacturing setup (less than 6 months) Depending of the manufacturing volume, dedicated manufacturing testing tools and processes may need to be implemented and validated. This phase consists of moving from a low volume pre-serial unit manufacturing to an easily repeteable industrial process for upcoming batches.

Therefore, only 3 months are required from the inital concept to its first safety critical implementation and real world and a full industrial grade mass produced SIL4 application can be achieved in less than 2 years.

HIGHLY AVAILABLE

The CLEARSY Safety Platform has been designed to reach high availability. The predictive duration of the mean time between failure (MTBF) is larger than 12 millions hours (at 40°C).

For context where this availability is not enough, the vital computer board can be associated with a redundant architecture (active/active or active/passive) to increase even further the availability of the resulting system.

Fully owned solution

All the source code and hardware schematic used within the CLEARSY Safety Platform have been developed and are maintained by CLEARSY. Thus, the industrial risk associated with the CLEARSY Safety Platform can be reduced because any component of the platform can be audited or placed under escrow. No third-party tools or code source is used within the CLEARSY Safety Platform. Moreover, the compilation and generation toolchain are compliant with the T3 requirement level per the assessment of an independent accredited assessor.

PROVEN IN USE SOLUTION

The CLEARSY Safety Platform and associated controller is a proven solution that have already been deployed by CLEARSY on several systems used in revenue services:

- Platform screen door control system COPPILOT.M (Sao Paulo monorail certificate CERTIFER #8891/200-1 27 february 2017 – SIL4)

- Platform screen door control system (Stockholm City Line – certificate BUREAU VERITAS #63937410 march 2017 – SIL3)

- Vital remote IO system (certificate BUREAU VERITAS #7092509 July 2019 – SIL4)

- Platform screen door controller system DOF (Cross-River-Rail Brisbane – certificate BUREAU VERITAS #1632751 – SIL3)

Besides, Atelier B IDE, which makes it possible to design software from a formal model, is already used by key players in the rail market and runs more than 30% of metro automatic pilots around the world.

WHY CHOOSE THE CLEARSY SAFETY PLATFORM

- Ease of the certification process thanks to already existing certificate.

- Shorter time to market.

- Efficient use of the B formal method (savings on software unit tests and integration tests).

- Design effort focused only on the end-user specific application.

- Validate quickly a proof of concept with real hardware in the loop.

- Easily improve the SIL rating of a system by adding a local safety supervisor.

- Hardware for usual interfaces available right out of the box.

- Possibility of designing a distributed architecture where computing resources are closer to the actuators and sensors.

Linked to this components

Linked to this components