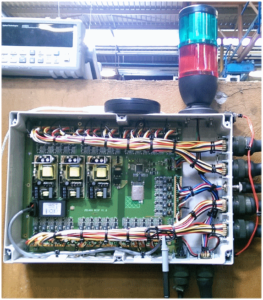

The CLEARSY measuring station allows to measure, verify and archive the values from the sensors. A processing board centralises the information from all the sensors and sends it via an Ethernet link (wired or wireless) to a PC which embeds the station’s control software.

Presentation of the system

The CLEARSY measuring station allows to measure, verify and archive the values from the sensors. A processing board centralises the information from all the sensors and sends it via an Ethernet link (wired or wireless) to a PC which embeds the station’s control software. This software allows the measurements to be launched, compared with a reference if necessary (as part of a control measurement), and archived in a SQL database (this database can be on the PC or on a remote server).

Documents and ISA* Certification

System description and benefits

Currently this CLEARSY product offers 36 analog 4-20 mA inputs and one 110V on/off input. The measurement is done simultaneously on all inputs. The measurement accuracy is 0.5% and measurements are made every 200 ms.

CLEARSY can produce a customised system with as many inputs as required and with as many types as desired (analogue, digital). The PC control software and the database structure will also be adapted to the needs of the customer and the project.

The advantages of this system

- Easy to archive measurements

- Full traceability of measurements (name of the operator, intervention number, etc.)

- Easy consultation thanks to a large choice of filters to find a previously taken measurement

- Ease of backup and restoration of the database

- Automatic control of all measurement values in relation to a given reference. Any type of control criterion can be added: response time, time to maximum value, maximum value, minimum value, average value…)

- Possibility to automate the measurements according to the process required for the measurement.

Application example: brake test bench

This system has already been implemented, for example, in the RTM (Régie des Transports Marseillais) metro maintenance workshop. It is used to periodically check the braking performance of a complete train.

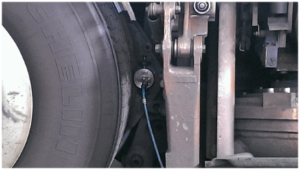

The sensors are distributed along the length of the train (about 100 meters from the processing board to the furthest sensor) and are installed at the time of measurement on the brake shoe axis of each wheel. The measurement is made by a custom-made sensor with an amplified 4-20 mA output. The braking force is therefore measured on each wheel of the train simultaneously.

The pneumatic pressure of the braking system is measured on each car via a pressure sensor. The train’s braking control is connected to an input on the processing board in order to start the measurement as soon as the driver brakes. This information provides an indication of the duration of the measurement (to obtain the braking response time in particular).

The photos show the pressure sensor and the acquisition device:

On this application are measured

- Braking effort on each wheel (32 measurements simultaneously)

- Pneumatic pressure of the braking system in each car

The system then performs the following processes

- Calculation of the braking response time (time to wait for maximum effort)

- Braking difference on one axle (delta)

- Comparison of results with a given reference (depending on the type of car)

- Archiving of the curves of each sensor as well as the information related to the measurement (operator, name of the train, intervention number, date, time…)

- Then we indicate whether the measurement is in accordance with the reference (see pictures in the gallery).