CLEARSY secures line 2 of the Marseille subway with its new system. The system has entered into service at the Capitaine Geze and rond-point du Prado stations. With its three functionalities, it aims to prevent the risks of collision/derailment and fire.

In Marseille, as in Paris, the trains run on wheels equipped with tyres, lined with wheels of slightly smaller diameter, made of steel. These do not, in principle, touch the rails. Safety wheels are also used to guide the train through the points. The traction current is returned (shunt) by means of third rail shoes lines attached to both sides of the bogies. But they also have a safety function, explains Patrick Sauvage, business manager at CLEARSY. It is thanks to the third rail shoes, and more precisely the third rail shoes of the lead and trailing cars, that the signalling system can locate the trains precisely, within each section of track (delimited by a track circuit). Detecting the absence of one or more third rail shoes is therefore a major safety issue. Our solution, says Patrick Sauvage, generates a magnetic field that will detect the absence of a skid using digital analysis software. The software was developed by CLEARSY.

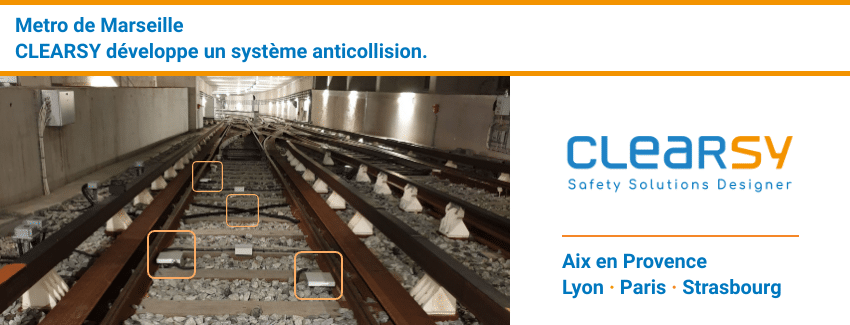

A third rail shoes that falls or is torn off can end up on the rails. But it can also fall into a switch and get stuck. The second feature of the system is the dragging equipment detector. It detects loose parts underneath the train that could damage the signalling equipment installed in the middle of the tracks. The dragging equipment detector is a metal part equipped with a sensor, 15 cm high and positioned in the middle of the track. It reacts to impact with any element detached from the train.

Trainsets on pneumatic tyres have the advantage of being less noisy. Problem: the tyres can deflate, degrade and catch fire under the effect of short circuits created by their metal carcasses between the traction rail and the metal track. Detecting tires that deflate reduces the risk of fire. The third functionality of the system is fulfilled by three iron wheel sensors on the track, a concentrator and an electronic box in a cabinet. “The first sensor detects the passage of the train, sensors 2 and 3, two per axle, detect the railway wheels that have come closer to the running rail due to the collapse of the under-inflated tyre. Thanks to this system, we can detect the deflated tyre, identify it and report it. Interfacing with the customer’s system is done by relay. This system is the subject of a patent registered by CLEARSY.

The CLEARSY system is installed at the beginning of the line, at the exit of the depot of the new Capitaine Gèze station, northern extension of line 2 and at the Rond-point du Prado station. After a series of successful tests in October, it went into operation.